December 19, 2013

Visit to the family (wind)Farm

In September, our family traveled to the west coast to visit with a variety of family and friends. One of our stops was in Tehachapi, the town where I did most of my growing up. My father, Bob Gates, is a wind industry pioneer and is a partner in a Techachapi area wind farm with which my family has been involved with for decades.

Some big new turbines were being put up on the site, so we wanted to go check out the construction. We met my sister Renata and her kids there and my dad took us on a tour.

The kids had a lot of fun running around and frolicking amongst industrial power generation machinery. Here are my three kids, my sister's three kids, and Becky, on a particularly windy knoll.

Grandpa was pleased to show the kids the construction equipment. This is a trenching machine for laying feeder cable.

Here are Allie, Violet, and Millie by the service building.

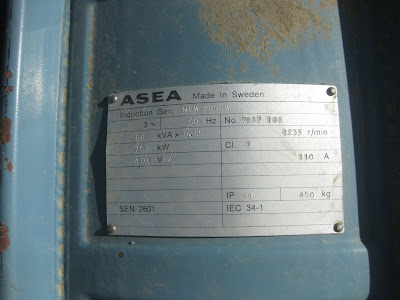

There are old parts of turbines all around, as you might expect of a nearly 30 year old wind farm. These are generators from the Vestas V15 or V17 turbines. My foot is for scale. I remember when these seemed big!

Nameplate.

While we were waiting for my dad to meet with a contractor, the kids played in the service building area. Here is Child 1 and his cousin Marcello sitting on a flat bed truck.

Millie found some old ribbon cable in the dirt and we used it to bind our wind park bouquets from the wildflowers.

The new turbines going up are HUGE. You can see each of the tower sections from this new turbine on the ground are nearly as big as one of the old turbines.

Growing up, I had a number of summer jobs at the wind company my dad worked for, and the biggest turbine I worked on had a 40 meter rotor. These new ones have 100 and 103m rotors, or over 6x the swept area! You can see the truck parked near the hub in this picture.

My sister's car next to a tower section.

You could live inside one of these.

My dad says at least on the last big turbine he was involved with that ring on the base of the tower section is forged. Can you imagine the machine that does that forging??

The blades are also mind boggling in their length and size.

Here is Bob showing off the bolt flange on the base of a blade.

Check out the hub, shrink wrapped next to the white car on the left.

Of course with big turbines, you need a big crane to put them up.

There was also a smaller crane, to put together the big crane.

Back Story

Tehachapi is small town at the south end of the Sierra Nevada mountains which occupies a mountain pass between the central valley and points south and east of there. Because of this geographical and topographical situation, it is extremely windy.

Zond

I mostly lived in Tehachapi from 1st grade until I went to college. My father, stepmother, and I moved there when I was about 6 (early 80's) with Zond Systems, a small company which was turning its efforts to wind power. Here is an interview with Jim Dehlsen, the original founder and first president of the company.

This patch of property is on a windy ridge between Tehachapi and Mojave, and was the location for some of the wind projects built by Zond. I have heard that this area was divided up into little parcels by the time the wind company arrived in the very early 80s, owned by an array of folks imagining that any day the suburbs of LA would stretch up that far (>2hr drive) and they could then sell them to developers at inflated prices. These parcels were exposed, windswept, and barren, with a fabulous view of a cement plant and the freeway. I think the place has a stark and elemental beauty and I could see living up there, but it's not in the least like suburbia. They had no power, water, sewer, or even road access rights. But these parcel owners felt like they were sitting on solid gold. Sheesh.

The first real wind farm of any scale in America was built on this land. I remember driving in 4WD vehicles up there and walking around before anything was built on it. We went sledding there, went to watch meteor showers there, had picnic style company parties. I sometimes worked there with after school or summer jobs for the wind company. I remember many a time going with my dad late in the night in a blizzard up on the hills to curtail turbines when the projects were making too much power for Edison. When I was a teenager, my dad taught me to drive on these steep dirt roads in an old truck (can't tell you how many times I stalled that truck when starting while parked on a hill!).

In those ancient years of alternative energy so much depended on the tax policy of the state of California, and the whole business landscape could change overnight according to the whims of the state legislature. Jerry Brown essentially created the industry during his first stint as governor, and conditions remained good for a few years.

Over the years, that original land was filled up with several waves of wind development projects. Conditions got tough for wind in the latter 80's, then started looking up again in the mid 90's. Zond was acquired in 1997 and after other corporate transitions became the core of GE Wind, one of the premier suppliers of wind turbines worldwide. They still have an assembly plant in Tehachapi.

This particular site has hundreds of Vestas V15 and V17 turbines, with 50-100kW rated output. These are significantly beyond their design lifetime, and require TLC to keep running well.

It is amazing how well these machines can still run with the right attention though. This is rotating machinery, operated for 30 years in extreme temperatures outdoors. I can only aspire as an engineer to design and build things which will be so durable.

One of the main ideas about how to make these older wind sites more productive is to repower them. This site is excellent from a wind resource standpoint, and there was a new transmission line coming in nearby to collect power from wind and solar projects in the Tehachapi and Antelope Valley region.

The partners worked to line up a developer to come in and put up some big new turbines (which make a lot more power than the old ones). In the end Terra-Gen (the developer) was able to make one project out of putting up some turbines on this site and a greater number on adjoining GE owned land, to feed into the new transmission line. Terra-Gen had already been active in the area repowering a number of the other nearby older wind farms. This collection of projects is called the Alta Wind Energy Center, and collectively it apparently can be considered the biggest wind farm in the world. The project being built here is called Alta 11, and the construction company doing the work is Blattner Energy. The way these things go, the project will presumably be sold to an investor after it is done.

The new project was in serious jeopardy when the PTC was about to expire. Of course this seems to pretty much always be the case with wind projects, though some think this won't necessarily be the case in the medium term future. Possibly the most damaging aspect of the PTC coming and going is lack of certainty for project planning of whether PTC is going to be there or not. But in this instance the PTC got a one year extension as part of the early 2013 fiscal cliff avoidance package. So full steam ahead!

What worked out in the plan that would fit on the site was a number of GE's 1.6MW, 100 meter rotor on 80 meter towers, and handful of GE's new 2.85MW, 103 meter rotor on 80 meter towers.

Construction started over the summer.

Road and pad grading.

Scores of the legacy turbines had be relocated to make room for the new ones and the new roads to get the giant parts in on trucks.

Rebar for a new foundation.

A poured foundation. My dad thought it took about 45 trucks of concrete per foundation.

The towers arrived by train.

Fortunately there is rail access quite close to the site.

Erecting the towers.

Blades coming in.

Lifting a rotor. See the person on the nacelle?

The storied history of the site means it is beset by a thatch of transmission lines. I think the Y shaped towers on the far left might be the new one.

My father reports that all the new turbines are up and are now being commissioned.

Between the legacy Vestas turbines and the new GE ones, the nameplate capacity of the machines on Windstream exceeds 70MW. This is enough to power over 20,000 homes. That's a product I can be proud to see coming off the ol' farm!

December 5, 2013

Black wool skirt, white cotton dress shirt

It is the time of year which brings the fall Revels Share Day, so both Violet and Millie needed a nice looking outfit with white on top, black on bottom. Violet has outgrown the white shirt I made for her last year for the Revels show, but with the cuffs folded back one extra time it fit great on Millie. Violet had some black pants, but Millie didn't really have anything to wear on the bottom. So I began working on a white shirt for Violet and a black skirt for Millie on the Sunday before the show.

Labels:

sewing projects

Subscribe to:

Comments (Atom)