December 19, 2013

Visit to the family (wind)Farm

In September, our family traveled to the west coast to visit with a variety of family and friends. One of our stops was in Tehachapi, the town where I did most of my growing up. My father, Bob Gates, is a wind industry pioneer and is a partner in a Techachapi area wind farm with which my family has been involved with for decades.

Some big new turbines were being put up on the site, so we wanted to go check out the construction. We met my sister Renata and her kids there and my dad took us on a tour.

The kids had a lot of fun running around and frolicking amongst industrial power generation machinery. Here are my three kids, my sister's three kids, and Becky, on a particularly windy knoll.

Grandpa was pleased to show the kids the construction equipment. This is a trenching machine for laying feeder cable.

Here are Allie, Violet, and Millie by the service building.

There are old parts of turbines all around, as you might expect of a nearly 30 year old wind farm. These are generators from the Vestas V15 or V17 turbines. My foot is for scale. I remember when these seemed big!

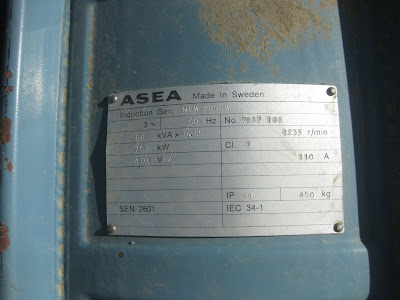

Nameplate.

While we were waiting for my dad to meet with a contractor, the kids played in the service building area. Here is Child 1 and his cousin Marcello sitting on a flat bed truck.

Millie found some old ribbon cable in the dirt and we used it to bind our wind park bouquets from the wildflowers.

The new turbines going up are HUGE. You can see each of the tower sections from this new turbine on the ground are nearly as big as one of the old turbines.

Growing up, I had a number of summer jobs at the wind company my dad worked for, and the biggest turbine I worked on had a 40 meter rotor. These new ones have 100 and 103m rotors, or over 6x the swept area! You can see the truck parked near the hub in this picture.

My sister's car next to a tower section.

You could live inside one of these.

My dad says at least on the last big turbine he was involved with that ring on the base of the tower section is forged. Can you imagine the machine that does that forging??

The blades are also mind boggling in their length and size.

Here is Bob showing off the bolt flange on the base of a blade.

Check out the hub, shrink wrapped next to the white car on the left.

Of course with big turbines, you need a big crane to put them up.

There was also a smaller crane, to put together the big crane.

Back Story

Tehachapi is small town at the south end of the Sierra Nevada mountains which occupies a mountain pass between the central valley and points south and east of there. Because of this geographical and topographical situation, it is extremely windy.

Zond

I mostly lived in Tehachapi from 1st grade until I went to college. My father, stepmother, and I moved there when I was about 6 (early 80's) with Zond Systems, a small company which was turning its efforts to wind power. Here is an interview with Jim Dehlsen, the original founder and first president of the company.

This patch of property is on a windy ridge between Tehachapi and Mojave, and was the location for some of the wind projects built by Zond. I have heard that this area was divided up into little parcels by the time the wind company arrived in the very early 80s, owned by an array of folks imagining that any day the suburbs of LA would stretch up that far (>2hr drive) and they could then sell them to developers at inflated prices. These parcels were exposed, windswept, and barren, with a fabulous view of a cement plant and the freeway. I think the place has a stark and elemental beauty and I could see living up there, but it's not in the least like suburbia. They had no power, water, sewer, or even road access rights. But these parcel owners felt like they were sitting on solid gold. Sheesh.

The first real wind farm of any scale in America was built on this land. I remember driving in 4WD vehicles up there and walking around before anything was built on it. We went sledding there, went to watch meteor showers there, had picnic style company parties. I sometimes worked there with after school or summer jobs for the wind company. I remember many a time going with my dad late in the night in a blizzard up on the hills to curtail turbines when the projects were making too much power for Edison. When I was a teenager, my dad taught me to drive on these steep dirt roads in an old truck (can't tell you how many times I stalled that truck when starting while parked on a hill!).

In those ancient years of alternative energy so much depended on the tax policy of the state of California, and the whole business landscape could change overnight according to the whims of the state legislature. Jerry Brown essentially created the industry during his first stint as governor, and conditions remained good for a few years.

Over the years, that original land was filled up with several waves of wind development projects. Conditions got tough for wind in the latter 80's, then started looking up again in the mid 90's. Zond was acquired in 1997 and after other corporate transitions became the core of GE Wind, one of the premier suppliers of wind turbines worldwide. They still have an assembly plant in Tehachapi.

This particular site has hundreds of Vestas V15 and V17 turbines, with 50-100kW rated output. These are significantly beyond their design lifetime, and require TLC to keep running well.

It is amazing how well these machines can still run with the right attention though. This is rotating machinery, operated for 30 years in extreme temperatures outdoors. I can only aspire as an engineer to design and build things which will be so durable.

One of the main ideas about how to make these older wind sites more productive is to repower them. This site is excellent from a wind resource standpoint, and there was a new transmission line coming in nearby to collect power from wind and solar projects in the Tehachapi and Antelope Valley region.

The partners worked to line up a developer to come in and put up some big new turbines (which make a lot more power than the old ones). In the end Terra-Gen (the developer) was able to make one project out of putting up some turbines on this site and a greater number on adjoining GE owned land, to feed into the new transmission line. Terra-Gen had already been active in the area repowering a number of the other nearby older wind farms. This collection of projects is called the Alta Wind Energy Center, and collectively it apparently can be considered the biggest wind farm in the world. The project being built here is called Alta 11, and the construction company doing the work is Blattner Energy. The way these things go, the project will presumably be sold to an investor after it is done.

The new project was in serious jeopardy when the PTC was about to expire. Of course this seems to pretty much always be the case with wind projects, though some think this won't necessarily be the case in the medium term future. Possibly the most damaging aspect of the PTC coming and going is lack of certainty for project planning of whether PTC is going to be there or not. But in this instance the PTC got a one year extension as part of the early 2013 fiscal cliff avoidance package. So full steam ahead!

What worked out in the plan that would fit on the site was a number of GE's 1.6MW, 100 meter rotor on 80 meter towers, and handful of GE's new 2.85MW, 103 meter rotor on 80 meter towers.

Construction started over the summer.

Road and pad grading.

Scores of the legacy turbines had be relocated to make room for the new ones and the new roads to get the giant parts in on trucks.

Rebar for a new foundation.

A poured foundation. My dad thought it took about 45 trucks of concrete per foundation.

The towers arrived by train.

Fortunately there is rail access quite close to the site.

Erecting the towers.

Blades coming in.

Lifting a rotor. See the person on the nacelle?

The storied history of the site means it is beset by a thatch of transmission lines. I think the Y shaped towers on the far left might be the new one.

My father reports that all the new turbines are up and are now being commissioned.

Between the legacy Vestas turbines and the new GE ones, the nameplate capacity of the machines on Windstream exceeds 70MW. This is enough to power over 20,000 homes. That's a product I can be proud to see coming off the ol' farm!

December 5, 2013

Black wool skirt, white cotton dress shirt

It is the time of year which brings the fall Revels Share Day, so both Violet and Millie needed a nice looking outfit with white on top, black on bottom. Violet has outgrown the white shirt I made for her last year for the Revels show, but with the cuffs folded back one extra time it fit great on Millie. Violet had some black pants, but Millie didn't really have anything to wear on the bottom. So I began working on a white shirt for Violet and a black skirt for Millie on the Sunday before the show.

Labels:

sewing projects

November 28, 2013

Making a Witch Broom

Millie wanted to be a witch for Halloween this year. We didn't have a good broom to use as a costume prop, so I told her we could make one. I took a deadwood stick from the woods in back of my office, and cut some dead weeds around the edge of the parking lot. We got started on the Saturday before Halloween.

I whittled the bark and nubs off the stick, then gave it a light sanding and finally a buffing with a non-woven abrasive pad. In the course of this, the end was rounded off.

We separated the grasses and threw out the ones that were too short. I had gathered two kinds, and one had a soft brush type feature at the top. These were saved for the middle of the broom bristle bunch, while the others were to be arrayed around it.

The bristles were arranged into small bunches. We used some extra wool yarn to bind the bunches together, with a clove hitch around the top of each.

Millie fired up the hot glue gun to assist us in attaching the bristles to the stick.

A little glue was put under each bunch of bristles as they were layed in around the stick.

The same yarn was used to make a bigger binding wrap, two layers thick, around the whole brush.

Finally, we trimmed the bottom of the bristles even and gave the tops some additional shaping.

Turned out great!

Millie was very pleased with it.

She rode it around witch style to try it out.

It did drop some bristles, but generally held up pretty well.

Violet and Millie worked on the rest of their costumes, which involved stringing and gluing plastic beads and feather boas.

Violet was a Snow Fairy, building on a white bride dress I made her a few years ago.

Millie's costume utilized a black dress I made the girls a while ago for my grandmother's funeral.

They were both very pleased with their costumes. Violet broke her wrist a couple days after these pictures and was worried her cast wouldn't fit through the costume. We got it in there though.

Child 1 wore a cute lion costume which Becky's friend Kelly brought us.

We also made jack-o-lanterns using the pumpkins we got when we went apple picking this year.

Labels:

family

November 12, 2013

Cider 9: making 800 liters of cider in one day, by bicycle power

For the 9th year running, we made cider. Most of the last 9 years' cider get togethers have been organized by Ben Polito and his family, and have been hosted at their holdings in Five Islands, Maine. This year the weather was perfect, everything went smoothly, and people generally enjoyed themselves.

Ben's writeup on year 9 can be found at his blog.

Friday

We arrived on Friday late afternoon and had time to unpack a little, settle into our rustic accomodations, and enjoy a nice dinner by the water with Ben's family and much of the Maine based cider crew.

The xB was happy to be de-freighted at the barn.

This was year two in the big barn Ben's family built on his grandparents' land, which is very convenient for running the cider production and associated meals. As can be seen in the picture, it is still getting finished, but its coming along nicely.

Most of the year, our custom designed and built cider machines sit idle in the barn, waiting patiently to be hauled into position and given their chance to rapidly process vast quantities of apples with extreme efficiency. Improvements this year were the addition of a bulk mixing tank, and an improved apple washing system.

Saturday

Ben had bought some supplies to cobble up an improved wash station, since washing apples has been one of the more arduous and time consuming tasks in years gone by. B.Wilkins and I built a wooden frame which divided a galvanized washtub full of water into two halves. Four brushes were screwed down to this, forming two V shaped brush channels spanning the wooden frame and linking one side of the tub to the other. In practice, this is how it goes:

First, some apples are loaded into buckets, in this case by Millie and Ilana.

Next, apples get poured into one side of the tub, and another brush is used to scooch them across a V channel into the clean side. Violet is demonstrating here using a toilet brush (which Ben swears is new :).

From the output side of the wash tub. they are taken out, relieved of any heinously bad spots, and put into a bucket for the shredder crew. Child 1 enjoyed moving apples from the wash bucket to the shredder input bucket.

This new system was faster and more pleasant than swooshing around apples by hand in a bucket of water, and did a much more thorough job of washing too.

The shredder has been kicking it out the last couple years with remarkably few issues.

By far the highest number of joules required by this operation go into the shredding. Even with two bikes yoked to it, one still gets some brisk exercise while pedaling one of the cycles. Note the highly functional sideways sway stabilizer in the back crate below.

The core fodder for the hard cider mix included about 300kg Ben picked at Poverty Lane in New Hampshire. This included Yarlington Mill, Wickson, Kingston Black, Bramtot, Stoke Red, Michelin, and some russets. We also ran a bunch of buckets of wild apples picked by Ben's parents Dave and Emily from around Georgetown island. Among them were some buckets of an interesting apple which looked just like a golden russet, but was more crisp and a lot less sweet.

The press itself operated quite smoothly. Much of this is down to operator skill level increasing in regards to how to load and fold the fabric pack tiers of shredded apple, called cheeses.

Ben set up a hand operated bilge pump to move the output of the press up into a 400 liter conical US Plastics tank, perched in its steel cradle on top of an elevated stand Dave put together. This arrangement eliminated the time consuming and finicky task of pouring cider from pots into many small bottles, and also allowed better blending between press loads (which are often composed of only one or two varieties of fruit). We filled up the bulk tank with cider from a mix of apples destined for fresh consumption, then dispensed from the bottom of the tank through a hose into the prepared plastic bottles.

The filler fruit for the hard cider run and most of what went into the sweet mix came from Autumn Hills in Groton, MA. Andy, a long time cider attendee, works as a farmer and has a relationship with the orchard for supplying fruit for his CSAs. So he was able to hook us up with about 500kg of mixed packing rejects. Ben graciously drove down from Maine to load and transport these apples, and gathered 100kg or so of Rhode Island Greening drops to boot. I brought about 60kg of Greenings and what I think is Yellow Delicious, which we picked some weeks earlier (brought to Maine by Aaron Schmidt, as our car was FULL). Other folks also brought in apples in varying quantities, including some nice wild apples supplied by Becky's friends Stephanie and Antonio from their place in ME.

After the bulk tank was full with the hard cider mix, compressed air was fed into the bottom port to assist in mixing. Then the waiting line of glass and plastic carboys was filled, with just a tiny bit left over.

The weather was lovely enough to kick back on the grass outside the barn. Here is Becky and Violet crocheting, Millie and Child 1 taking a break from running amok.

In parallel with making this year's cider, several carboys of last year's hard cider were carbonated and bottled. We set up a trash can full of ice water, which could accommodate three corny kegs loaded with cider and under pressure from a 9kg CO2 tank. With agitation, these chilled down and carbonated fairly quickly and were used in sequence to feed Ben's double barreled counterpressure bottling rig.

Food

Saturday breakfast was mainly provided by the Wilkins with a smattering of dishes brought by others. Ben's parents provided the bulk of lunch with a 40L stainless cream can full of potatoes, sweet potatoes, cabbage, carrots, sausage, and corn which had been simmering with beer all morning over a propane turkey cooker. Apparently this is a well known thing in Nebraska, and a quite handy way to generate large quantities of food with modest amounts of work.

An excellent technique which we employed several times this year, starting with the cream can meal, was the dumping of huge loads of hot food straight into a clean cooler. The food could be served conveniently right out of the cooler, which keeps it warm and has a lid to keep wasps out and moisture in.

Soup and Sausages

Becky and I started working on dinner food at around 3pm. Ben brought a pile of butternut squash from Stroudwater; Becky used 5 of those I think. Andy the farmer also brought some other veggies to put in the soup. While I was busy with pie and bread, Becky cooked up a delicious squash soup in our large pot over a turkey cooker, which was dumped into a cooler when it was done. We brought a bunch of sausages for dinner too. These got cooked in Ben's giant new Cabelas cast iron skillet (~400mm diameter!) on a turkey burner.

Pies

A few weeks before cider, I turned about a bushel (18kg) of apples we picked into 8 prepared pie fillings, packed individually and preserved in the deep freeze. There is some advantage to doing more fillings at once, since you save on the overhead of set up and clean up. Each filling was composed of

- 1100g of peeled, cored, apples (Rhode Island Greenings, Yellow Delicious, and Empire this time)

- 1/4c white sugar

- 1/8c boiled cider

- pinch salt

- 1 tsp cinnamon

- juice from 1/4 lemon

- 1/8c corn starch

I first peeled and cored, using my trusty antique Reading peeler, weighing as I went and dividing among two large vessels.

Then everything but the corn starch was put in, mixed, and allowed to macerate for 45 minutes.

The drained liquid was boiled down in a saucepan while I divided the apples among 8 ziploc bags. Once the liquid was reduced and thickened, it was divided equally among the bags, then the cornstarch was added to each and they went into the deep freeze. Four of these fillings came to cider, serving as the ice packs in the insulated grocery bags we used to bring all the groceries for dinner prep.

Then everything but the corn starch was put in, mixed, and allowed to macerate for 45 minutes.

The drained liquid was boiled down in a saucepan while I divided the apples among 8 ziploc bags. Once the liquid was reduced and thickened, it was divided equally among the bags, then the cornstarch was added to each and they went into the deep freeze. Four of these fillings came to cider, serving as the ice packs in the insulated grocery bags we used to bring all the groceries for dinner prep.

Bread

A week before cider, I cultured and churned 2L of cream into butter and buttermilk, much like in this older post. This butter got salted and molded for taking to cider to eat on fresh bread. Some of the buttermilk went into the pie crusts, the rest went for pancakes, waffles, and cold cucumber soup.

In preparation for cider weekend, I had been working on scaling up baguette-like bread baking. I worked out both a whole grain and a white recipe based on a full 2270g (5lb) bag of flour. For cider, I ended up making 24 loaves of bread in two batches in Ben's grandparents' oven. It was late as usual, dang it. Here are the ingredients for the white batch.

Starter

- 1700g King Arthur unbleached all purpose flour

- 1700g water

- 1/8 tsp instant yeast

Supplement

- 570g flour (rest of bag)

- 1 tsp instant yeast

- 40g kosher salt

For the whole grain batch, I did:

Starter

- 1400g AP whole grain soft white winter wheat flour from Wild Hive

- 1400g water

- 1/8 tsp instant yeast

Supplement

- 100g whole grain rye flour

- 100g vital wheat gluten

- 670g AP SW winter wheat flour

- 1/2c olive oil

- 1/2c local honey

The below pics are from test batches, since I was way too harried at cider to document the process there.

Process

Mix up the starter, let it go overnight.

The next morning, add the other ingredients and do about 20-40 folds with a scraper in an oversize container holding the dough.

Every 20-30 minutes, do a couple stretch and folds, total of 3 cycles beyond the initial mixing. Let ferment all day. At cider, I put out the two tupperwares in the sun mid-day since I thought they needed a boost.

Turn dough out on well floured counter, do one last stretch and fold, divide into 12 chunks using scraper.

Let rest for about 45 minutes. Shape into loaves, deposit on parchment lined baguette pans.

I bought a couple more pans before cider weekend, so I could have a total of four 3 loaf pans. This totally fills the racks in a home oven, which makes baking heat pretty uneven. But if you rotate and flip the loaves during the latter half of baking, its ok if not ideal.

Let proof for 45 minutes, slash, bake for about 20-25 minutes at 240C (460F) in a well preheated oven, preferably with a stone on the bottom. Cool for at least 10 minutes.

Enjoy with big slabs of delicious butter!

This bread turned out pretty well, besides being ready later than intended. It does bake much more evenly with only one pan per oven rack, but doubling the throughput is useful sometimes even with its drawbacks. The whole grain has an excellent sweet, nutty flavor, but doesn't rise as well as the white.

There was actually a ton of food at dinner, both leftovers from lunch and breakfast as well as food brought by attendees. There were 46 people present for dinner, down from the peak activity period in the afternoon. Plenty of food was leftover from dinner; much of it eaten on Sunday for breakfast and lunch.

Josh K. and Kelsey cooked up some fine blueberry pancakes for breakfast on Sunday, once again putting Ben's giant iron skillet to good use. There was even some apple pie left from the previous night.

Sunday

Ben did much of the remaining cleanup and stowed the cider equipment on Sunday.

Child 1 helped wash some press grates.

We had to leave pretty early on Sunday to get back to town for Chinese School at 2pm in Lexington. I started taking the girls to this in September, and we had already missed two weeks for a trip out west. So I thought it would be good if we made it back for that, despite the fact that we all wanted to enjoy a few more hours of a beautiful fall day in Five Islands. Here we are saying goodbye to Ben. Becky is explaining our dreams about landscaping our back yard in Somerville; Ben is looking at her like she is a total nutball.

The xB was packed up pretty full for both legs of the trip.

We brought back a heavy load of cider. I was planning on freezing about half a carboy of cider for drinking sweet later, but our deep freeze is chock full of chickens at the moment due to some interesting planning regarding our meat CSA. As a result, I froze all the small bottles of cider we brought back, but ended up starting a 6th carboy fermenting to hard cider.

Hard Cider Progress

In this picture, I have a halogen work light plugged in underneath the carboys. The front left two were having trouble getting started, so I left the light under there for a couple hours while I attended to other business in the basement. This did the trick nicely and both had developed a rich head of foam by the next day.

Several weeks having passed at this point, I just racked this cider into secondary last weekend. One of the airlocks had somehow come off a carboy, but I racked it anyway and will hope for the best. Worst case maybe I can turn it into a few years worth of cider vinegar.

During racking I tasted the young cider. Of course it is very yeasty at this point, and sweeter and tarter than it will ultimately become, but to my palate it is shaping up quite nicely.

Subscribe to:

Posts (Atom)