|

| Wheeler & Wilson No. 9 |

Looking forward to starting my new life free from commercial clothing vendors, I began cruising craigslist and ebay for a suitable treadle table to house my newly acquired Necchi BU Nova. Becky and I agreed that a good looking treadle table would be best located in the dining room, where we could use is as a little sideboard or side table to put flowers when it is closed up. As you might expect, there were plenty of options on craigslist for cheap, but I was picky and wanted something that looked (or could look) great, was in reasonable shape and so wouldn't need a ton of work, and also not too big in size.

So I bought this Wheeler and Wilson No. 9 from a guy in Salem, who was kind enough to deliver it for an extra fee.

Wheeler and Wilson was once the biggest sewing machine manufacturer in the world, and had an enormous factory in Bridgeport, CT with 5 acres of floor space. Allen B Wilson invented the rotary hook and the four motion toothed dog style fabric feed. The W&W 9 cost $60 in 1892. This is the equivalent of about $1500 in 2010 terms, and it is a high quality machine which has weathered the 120 years since it was made exceedingly well. The company was bought out by Singer in 1905 after a period of decline.

Above info is taken from SEWALOT, the informative website of Alex Askaroff.

Some other websites with info on Wheeler & Wilson:

Wheeler and Wilson at ISMACS

Wheeler and Wilson at sewmuse.co.uk

Wheeler and Wilson at Wikipedia

My machine looks to be an earlier model based on the longer bobbin cover plate and bigger balance wheel. Here is a shot of the patent dates on the right hand throat plate section. The latest patent date is 92, serial is 2563227.

Rejuvenation

Basically I followed the guidelines found at the Treadle On website. The girls and I took it apart and washed it with Murphy's oil soap. Then I treated the woodwork with Howard Restore-a-finish, which toned up the finish very nicely, plus I got it a shade darker to bring the tone of the finish closer to the other darker wood furniture in the dining room.

|

| The cleansing begins |

I took the iron parts and the head to the basement and hosed them down with WD40 (kerosene), then cleaned them all off thoroughly.

After drying I took these upstairs and got my helpers to give them a good waxing with Turtle Wax. This looked good to begin with, but after a while it got kind of dull and I wasn't able to buff it to a shine again. So I went over it again with Wax-n-Feed and it now looks great.

|

| Work crew applying Turtle Wax |

Millie helped me lube all the moving parts in the head and the iron base with Tri-Flow, and I went over some parts in the head with a metal polishing cloth. The polish didn't really do a whole lot, probably I need something stronger than what I used, but it still looks fantastic.

|

| Millie carefully adjusting the upper thread tension spring |

|

| Violet concentrating on trying to treadle |

Presser Feet

As you might expect with a machine of this vintage, it is a straight

stitcher and has a limited range of attachments. The presser foot is a

unique but very sturdy style which involves a vertical plate of the

presser foot being inserted and clamped into a vertical center slot in

the presser foot rod. This makes finding feet for it difficult. I'm

thinking of making an adapter for low shank feet; I've heard from a few

people that their machines came with such an adapter. I'd like to be

able to fit a buttonholer on it, but that would involve not only the

presser foot adapter, but also an adapter to connect the needle rod to

the power input arm of the buttonholer. A project for the future. |

| What is that little clip thing above the foot? |

There are frequently W&W machines and attachments on ebay. Search for "Wheeler Wilson". I bought a nice little wooden box with a bunch of attachments for $40; some are duplicates of what came with my machine. Anyone need a spare tucking foot for a WW9? Come on, don't laugh!

|

| Millie checking the lid lock action |

|

| Accessories and Manuals |

My machine came with a tattered operations manual, which I photocopied at work to make a usable version. Here is a version I scanned:

Wheeler and Wilson No. 9 Manual

The version visible in Google Docs doesn't look great, but there is a link to download the original pdf which looks and prints ok.

Dianne B. in England from the Treadle On list was kind enough to post the link to the Wheeler and Wilson No.9 manual at archive.org.

Also got an attachments manual with the machine, scanned copy is posted to Google docs:

Wheeler and Wilson No. 9 Attachments Manual

There is a different scanned copy of this manual at archive.org.

Needles

The

needle is not compatible with any currently made needles on the

market. It is longer, with a smaller diameter upper mounting shank than a

typical 15x1 needle. My machine came with 10 needles including one of each of the sizes listed on the front of the old manual, so that should

serve for a while. I read about an ebay seller, ngosew, who sells

some modern industrial machine needles which are not exactly the right

fit but apparently will work if lined up properly by hand. I bought some

of those but have not yet tried them out. Cindy Peters of Stitches in Time probably has some suitable antique needles. |

| Top - 15x1 needle Bottom - W&W No. 9 Needle |

Extras

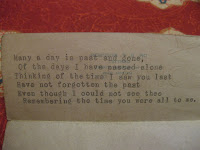

In the drawers of my machine, along with attachments, manuals, terminally weakened spools of thread on wooden cores, broken needles (why save them??), rusty pins, dust bunnies, etc., were some touching personal documents. These must have been dear to the heart of the former owner, to keep them for decades in the crowded drawers of a treadle sewing machine cabinet.

One was a ripped ticket from the launching of the USS Delphy dated July 18, 1918. This ship was an ill fated destroyer commissioned after WWI, which foundered on rocks off the coast of California in 1923. Was this husband or son's ship?

In another drawer was a little typed love poem, on the back of stationary from the dentist's office. Was the dentist her husband? Perhaps lover? The locking drawer of your sewing machine cabinet would be a great place to put a note from your lover, since no man could possibly have any call to look there.

If only this machines could talk. Lovely machine.

ReplyDeleteWhat a lovely tribute to this machine! Your family is darling, as well! Happy treadling!

ReplyDeleteSuch a lovely machine and your family too. The little clip thingy is a thread cutter.

ReplyDeleteI have this same machine. about to sell it. Was looking online for a value. Love what you have done. Hope you are still enjoying it.

ReplyDeleteWhat a lovely blog, so lovely to get your family interested in some history, and so kind to upload the manual-there are so many people out there who want to make money out of everything, Thank You.

ReplyDeleteI just acquired a W&W No.9. I have no belt. We mention getting a new one from McMaster-Carr. Could you please tell what you got exactly since I have nothing to go on.

ReplyDeleteThanks!

Actually I ended up continuing to use the old belt which came on it, even though it is in somewhat rough shape. I use it pretty frequently, though I need to shorten it slightly just now because it is getting a little loose and slipping too much.

ReplyDeleteMessages on the Treadle On group suggest 3/16 is the best replacement belt size. I got both leather and hollow urethane belting from McMaster:

http://www.mcmaster.com/#6567k1/=u8wdhv

http://www.mcmaster.com/#6170k12/=u8wfwu

and connectors for them

http://www.mcmaster.com/#6567k26/=u8wgdx

http://www.mcmaster.com/#catalog/120/1065/=u8wg2m

But I haven't yet tried them so I'm not sure how well they work. Treadle On people seem very happy with the urethane belting.

Thank you so much. I'm not sure I actually want to sew with it, but having that option would be pretty neat. It's refreshing to see that there are other people would love things as much as I do. :)

ReplyDeleteThank you for posting this!! My sister and I inherited this EXACT sewing machine (same table as yours too) from my great great grandparents. Everything seems workable, except that the belt is broken. I'm planning on using your suggestions for the new belt and teach myself and my daughter on how to sew using this. she kept all of the original pieces as well, just not he instructions. :)

ReplyDeleteLooking for some Boye needles for Wheeler Wilson treadle sewing machine. Any small size would do fine.

ReplyDeleteCindy Peters with Stitches In Time

DeleteSo from what I have found, the D9 and 9 series are from like 1897 to 1905 when Singer bought the company. My Wheeler and Wilson D9 has a serial number of 2826894, but I cannot find a manufacturing year for it. My husband and I think it is from 1902. We were told that hus Great-Grandma bought it new. I also want to say how happy I am that I found your blog as my husband amd I want to restore ours but had no idea how to go about it. If you have any advise, I would greatly appreciate the help.

ReplyDeleteIna - that is amazing that you have one of these as a family heirloom. It really is a great machine, despite it's limitations.

ReplyDeleteFor restoration, spend some time perusing the Treadle On webpages and archived emails. Here is a good place to start:

http://treadleon.net/sewingmachineshop/index.html

My machine was is decent shape so it wasn't that hard to get it going. Hopefully that is the case for you too. Obviously machines with more damage, rust, or missing parts are going to be tougher to bring up to usable condition. But if you are dedicated you will be able to do it even if you need to find replacement parts.